In the world of material handling, choosing the right conveyor system is critical to maximizing efficiency and minimizing operational downtime. One of the most popular and versatile solutions for a wide range of industries is the Hairise modular belt. These systems are known for their flexibility, durability, and ease of maintenance, making them an ideal choice for companies in sectors such as food processing, automotive, packaging, and pharmaceuticals. The Hairise modular belt offers unique features that cater to the needs of each specific industry, and its modular nature allows for a high degree of customization. The Hairise modular belt is designed to handle various tasks, from lightweight component transport to heavier-duty applications, all while maintaining operational efficiency. By offering tailored modular belt solutions, Hairise ensures that its systems can accommodate various production line requirements. Whether you’re looking for an easy-to-clean belt for food handling or a robust option for manufacturing environments, Hairise modular belt systems deliver reliability and superior performance. Each modular belt is engineered with precision to ensure smooth and safe movement of materials, contributing to enhanced productivity and reduced downtime. The modular belt is an investment in the future, designed for long-term use with minimal maintenance. Hairise’s innovation in modular belt technology is evident in the wide range of customizable options available, which cater to diverse industrial applications. The versatile nature of the Hairise modular belt makes it one of the most trusted names in material handling. With over two decades of experience in the field, Hairise continues to set the standard in modular belt conveyor systems.

The Versatility of Hairise Modular Belts

Hairise modular belts are known for their exceptional versatility, which makes them suitable for nearly every industrial application. From light-duty tasks to heavy-duty operations, the modular belt can be customized to meet specific requirements. The beauty of the modular belt system lies in its modularity, allowing for easy reconfiguration and adaptation as needs change. This modular nature makes it an ideal choice for industries where production processes evolve over time. In the food processing sector, for example, the Hairise modular belt is designed to handle a wide variety of products, from fresh produce to packaged goods. The ability to customize the modular belt for specific tasks, such as washing, sorting, or packaging, ensures that the conveyor system optimally supports every stage of the production process. Similarly, in automotive assembly lines, the Hairise modular belt can be configured to handle everything from small components to larger, heavier parts, helping to streamline operations and reduce bottlenecks. The adaptability of the modular belt makes it a go-to choice for companies that require flexibility in their material handling systems.

Moreover, the modular belt is known for its ability to handle various surface conditions. It is available in a wide range of materials, including stainless steel, plastic, and various composites, which are selected based on the demands of the specific industry. For example, in the pharmaceutical industry, the modular belt’s smooth, hygienic design ensures that products remain uncontaminated throughout the manufacturing process. In contrast, in the automotive sector, the modular belt can be configured with heavier-duty components to handle the movement of large car parts through high-speed assembly lines. Regardless of the industry, Hairise modular belts are engineered to ensure smooth, efficient, and reliable transport, making them indispensable for modern manufacturing operations.

Durability and Reliability of Hairise Modular Belts

When selecting a conveyor system, durability and reliability are essential. Hairise modular belts excel in these areas, offering long-lasting performance even in the most challenging industrial environments. The modular design of these belts provides an inherent advantage over traditional conveyor systems. Because the Hairise modular belt is composed of individual interlocking modules, damaged sections can be easily replaced without the need for a complete belt overhaul. This not only reduces maintenance costs but also minimizes downtime. Additionally, the modular belt’s robust construction is designed to withstand heavy loads, extreme temperatures, and abrasive materials. This makes the Hairise modular belt an ideal solution for industries such as mining, manufacturing, and recycling, where the conveyor system must handle tough conditions.

Another factor that contributes to the durability and reliability of Hairise modular belts is their resistance to wear and tear. Modular belts are designed with advanced materials that offer high resistance to abrasion, chemicals, and UV exposure, which extends the service life of the system. For example, Hairise modular belts can be manufactured with materials that are resistant to oils, grease, and other substances commonly found in industrial environments. These materials not only improve the belt’s performance but also help ensure that the modular belt operates efficiently for extended periods without needing frequent replacements. This results in significant cost savings over time, as businesses don’t need to continuously invest in new conveyor belts.

Easy Maintenance and Cleaning

Another key advantage of Hairise modular belts is their easy maintenance and cleaning. In industries like food processing and pharmaceuticals, hygiene and cleanliness are paramount. Hairise modular belts are designed to facilitate quick and efficient cleaning, reducing the time and effort needed to maintain compliance with stringent industry standards. The open structure of the modular belt allows for easier access to individual components, which means that cleaning personnel can quickly disassemble and reassemble the system when necessary. In addition, the ability to replace individual modules makes it simple to address any wear or damage without having to shut down the entire system.

The modular belt’s design also reduces the accumulation of dirt, debris, and bacteria, which are common concerns in industries that require high sanitation standards. The materials used in Hairise modular belts are selected for their resistance to bacterial growth, which helps maintain product integrity and minimizes contamination risks. Furthermore, the belts are designed to be easily cleaned with high-pressure washers or automated cleaning systems, ensuring that companies can maintain a high standard of cleanliness with minimal effort. This ease of maintenance and cleaning adds significant value to Hairise modular belt systems, making them a preferred option for businesses in sectors that rely on strict hygiene practices.

Customization for Specific Applications

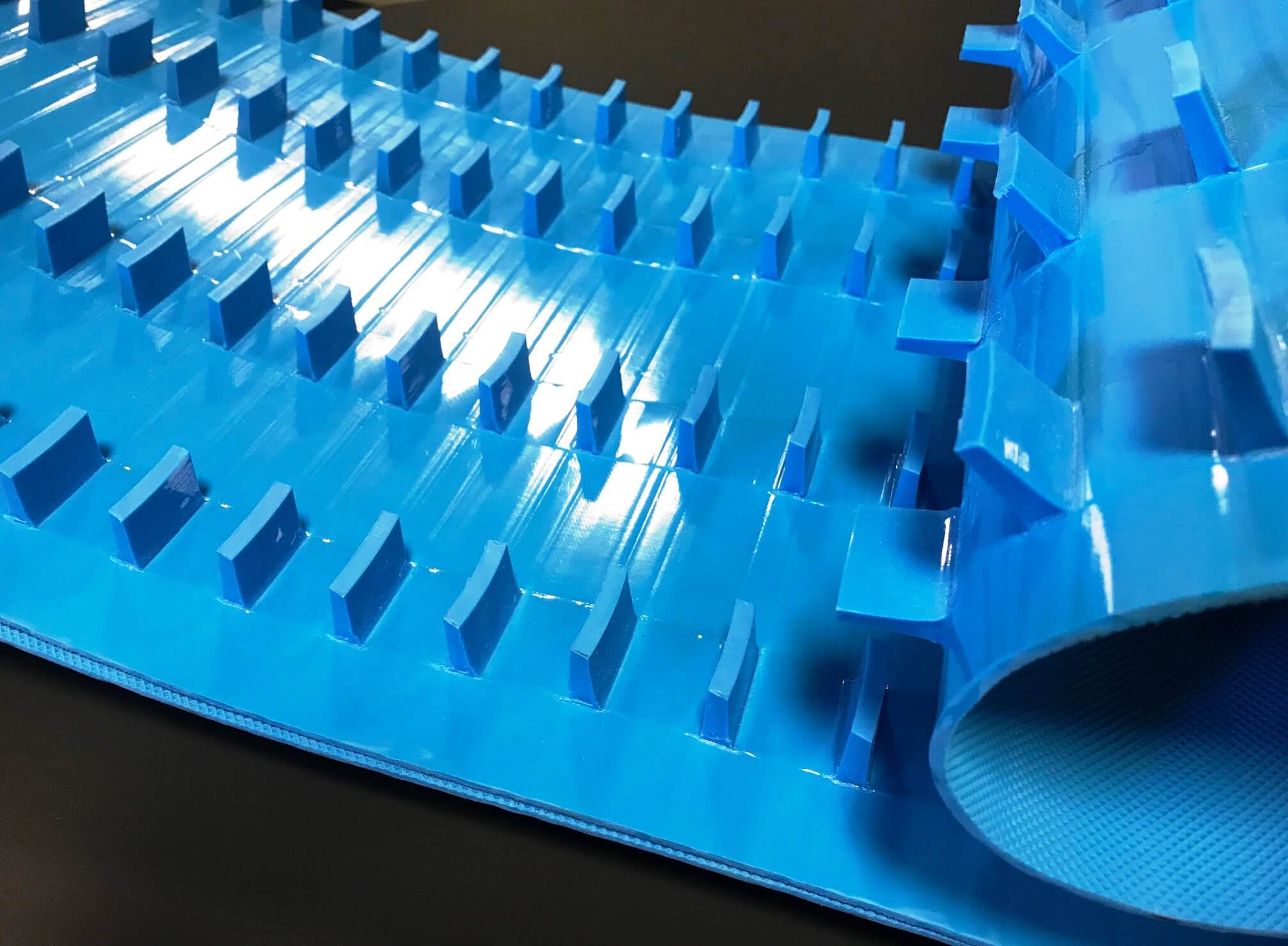

Hairise modular belts offer a wide range of customization options to suit the unique needs of different industrial applications. Depending on the type of product being transported, the modular belt can be designed with specific features to optimize performance. For instance, Hairise offers belts with different types of surface finishes, such as smooth, textured, or perforated, to accommodate varying product types. This allows businesses to tailor the modular belt to the specific material handling requirements of their production lines. For example, in the food industry, belts with a textured surface might be used to prevent slipping, ensuring that items stay in place during transport. On the other hand, in electronics manufacturing, smooth, low-friction belts can be used to ensure that delicate components are handled with care.

Hairise modular belts can also be designed with different widths, lengths, and configurations to accommodate a wide range of conveyor systems. This high level of customization makes Hairise modular belts an excellent choice for businesses that need a conveyor system that aligns perfectly with their production process. Whether you require a simple straight conveyor, a curve, or even a spiral design, Hairise can provide the ideal modular belt solution to meet your needs.

Conclusion

Hairise modular belts are a versatile, durable, and highly customizable solution for virtually every industrial application. Their ability to adapt to a wide variety of tasks, from light-duty to heavy-duty material handling, makes them a valuable asset for companies in industries such as food processing, automotive, pharmaceuticals, and manufacturing. With over two decades of experience, Hairise continues to innovate and develop modular belt systems that enhance productivity, reduce downtime, and ensure long-lasting performance. The modular design not only allows for quick and easy maintenance but also facilitates customization to meet the specific needs of each client. Hairise modular belts provide businesses with a reliable, cost-effective solution for all their material handling needs, making them a trusted choice for industries around the world.